Fabrication refers to any procedure that cuts, figures, or otherwise form stuff into a product. Plastic fabrication is a growing industry, as it forms the base for many other manufacturing processes. This article covers the benefits and dew backs of plastic over metal fabrication and more. The fabrication technique used to create a particular thing depends on an extensive range of factors, counting the good’s purpose, look, and accessible budget.

Types of Fabrication Process

Both plastic & metal fabrication occupies an extensive range of different manufacturing procedure. This range allows for a significant number of customization and collection options in constituent design. Some of the more ordinary fabrication processes include:

Cutting: This involves different tools or machines, removing extra material from a workpiece to rally size & shape needs. Band saws & cutting torches are two instances of cutting devices.

Plastic Forming: This procedure uses deforming tools, such as hydraulic brakes, to curve or press products at a particular angle.

Machining: The machining procedure includes lathing, milling, drilling & honing, using automated or manually proscribed equipment to form material.

Welding: In welding, two or more workpieces are joined by using heat or force to form a solitary product.

Lathing: Lathing is a cutting technique that utilizes a rotating worktable and split blade to cut, drill, knurl, or engrave the material. Lathing is most excellent suited for goods that are regular around an axis of the revolving

Drilling: This procedure employs a drill press to turn off holes into a creation. It is effective for creating consistent, circular cuts.

Honing: Honing involves numerous rotating tips that increase existing holes to precise sizes. It helps make goods that need big circular cuts, such as engine tubes.

Grinding: Grinders apply a rough wheel to surface delight material or make faint cuts in the product. Grinding is helpful for applications that need flat surface textures.

Benefits of Plastic Fabrication

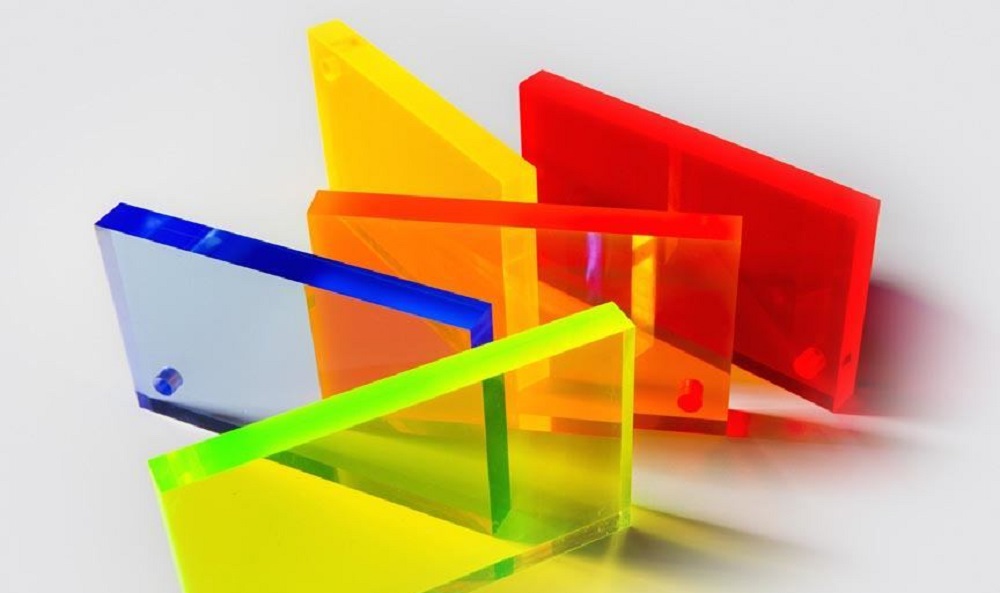

However, the results of plastic fabrication significantly depend on the exclusive characteristics of the kind of plastic used (acrylic, nylon, Plexiglas, etc.); the procedure of fabrication of plastic has myriad of advantages, some of which are mentioned below:

The Simplicity of Forming: Due to its lower melting point & high flexibility compared to other materials, plastic can be moulded into basic and multifaceted geometries with relative simplicity. You can design any shape and size with the help of plastic fabrication.

Reduced Finishing: Unlike other metals, plastics can be highlighted before manufacture; get rid of the need for certain post-treatment procedures, such as painting.

Faster Production: Plastic fabrication frequently involves rapid cycle times & quick turnover rates. Thus, plastic fabrication can be completed at a much faster rate than metal fabrication.

Lighter Weight: Plastics normally weigh less than metals of similar dimensions. This makes it easy to carry around and easy to transport, which is one of the main reasons for its popularity.

Chemical Resistance: Plastics are usually less susceptible to scratch from chemical reactions, such as oxidation or rust, than metals.

Limitations of plastic fabrication comprise:

Although plastic helps fabricate an extensive range of parts, it also has its share of limits as a manufacturing material which are mentioned below:

Limited Wear Resistance: Plastic has a limited resistance threshold for eminent temperatures, sharpness, and other acidic elements.

Structural weaknesses: Most plastics are unsuitable for high structural strength applications, such as weighty equipment components & most building materials.

The disadvantages of plastic fabrication are much less if you compare it with its advantages. Hence, if you have been thinking to start your project, you can always consider plastic over metal. However, make sure that you get high-grade plastic only to yield its advantages in the long run.